Sandblasting and Painting

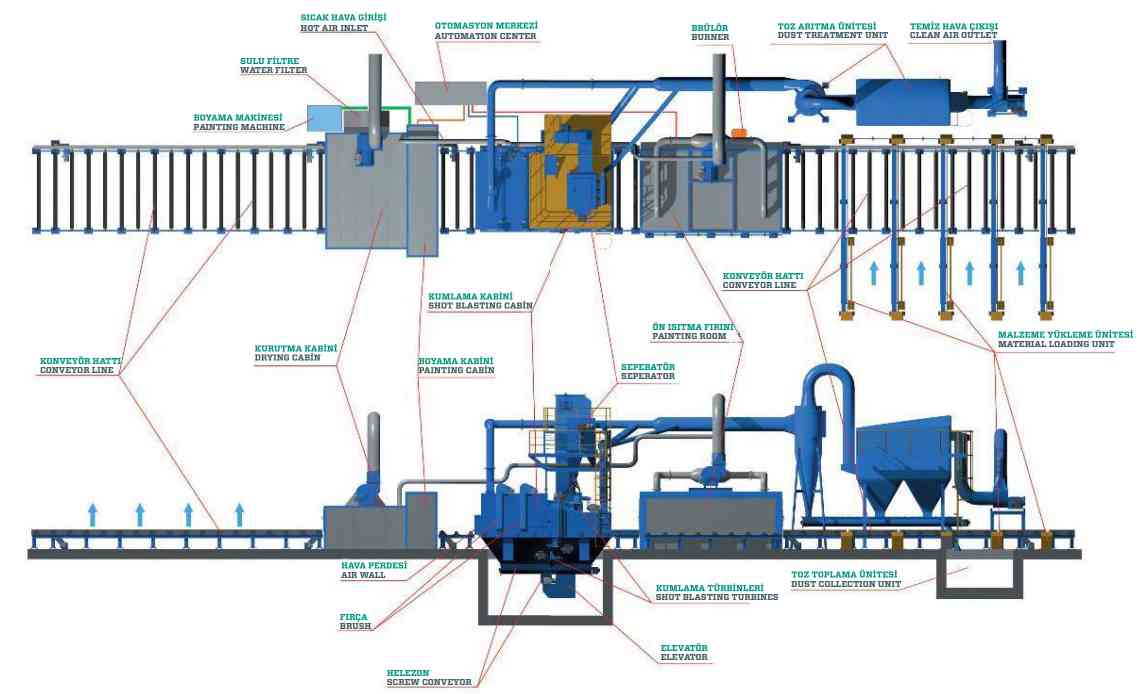

Fully Automated Shot Blasting And Painting Machine

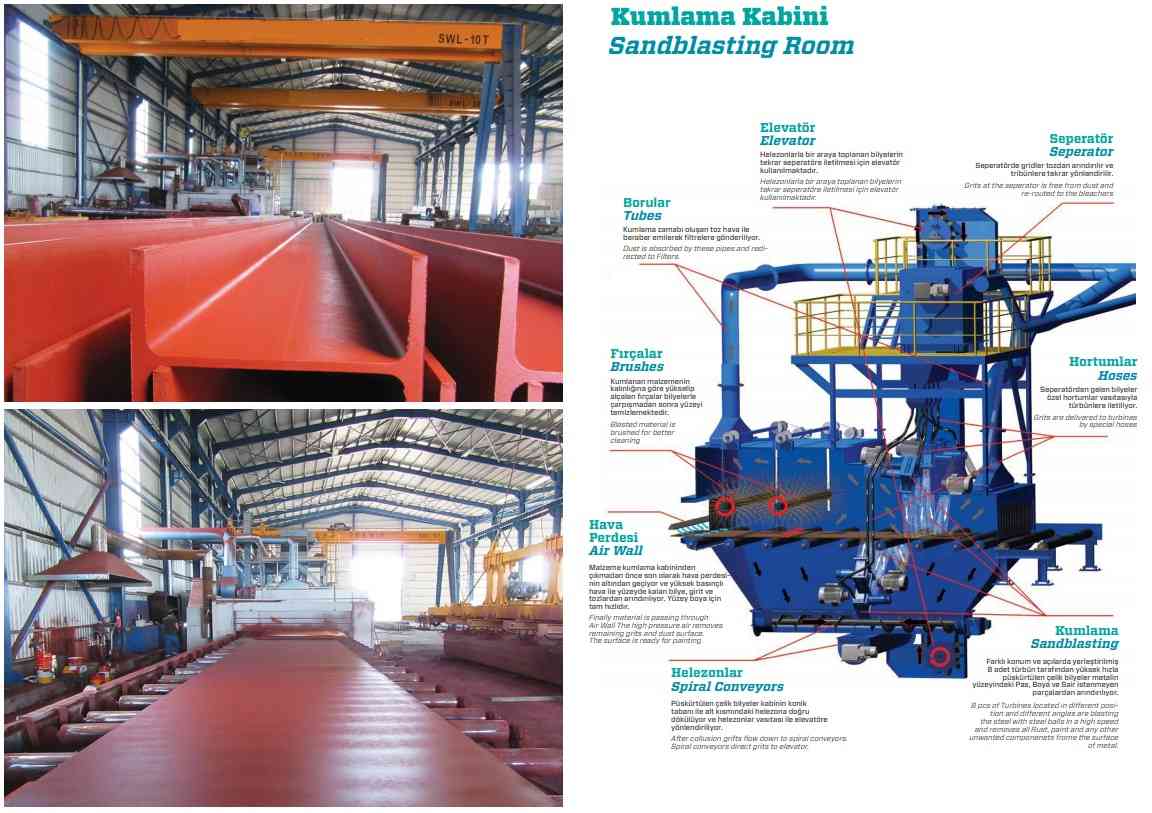

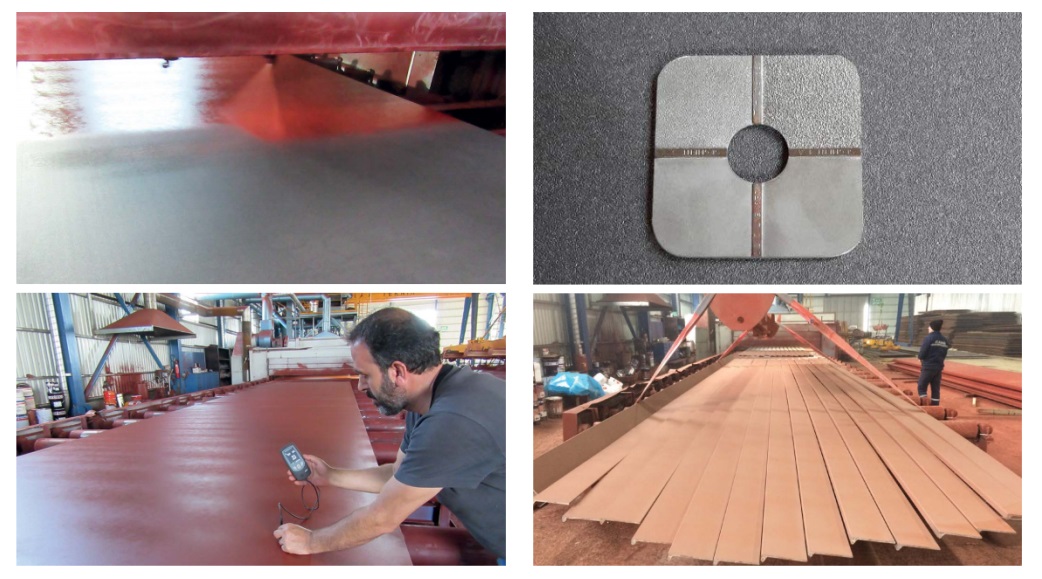

Our fully automated shot blasting machine can surface shot blast and primer coat materials such as plates, tubes and angle bars sized up to 3200mm wide and 600mm high. Materials placed onto hydraulic loading line are transferred onto entrance conveyor line by hydraulic and mechanic systems. On entrance conveyor forward speeds of 1.8 m/min are observed. In our preheating cabin with help of 2 gas burners internal temperature of the cabin can be increased up to 400˚C depending on weather conditions, which will increase the material temperature up to 35-40˚C. Materials leaving the preheating cabin are moved into the shot blasting cabin and here via turbines located at various angles, 4 on top and 4 at the bottom, by shooting bead particles rasping process is realized. Rasping process can be realized at any desired quality such as SA-2, SA-2.5 and SA-3. After rasping process bead particles and waste accumulated on surface are swept with brushes and then by wind curtain remaining dust and waste are completely cleaned off the surface. Following cleaning works top and bottom painting is done by robots. 18-25 micron thick primer coat is applied. After painting the materials are passed through a drying cabin onto exit conveyor and moved from here into storage area ready to be shipped.

Shot Blasting and Painting Hall Machinery and Equipment

26m x 85m Hall

* Fully Automated Shot Blasting and Painting Machinery Line

* 1pc 20ton Winch

* 2pcs 10ton Winch

* 60ton Weighbridge

* 2pcs 10ton Vacuum Sheet Lifting Device

* 1pc 8ton Lifting Capacity Magnet