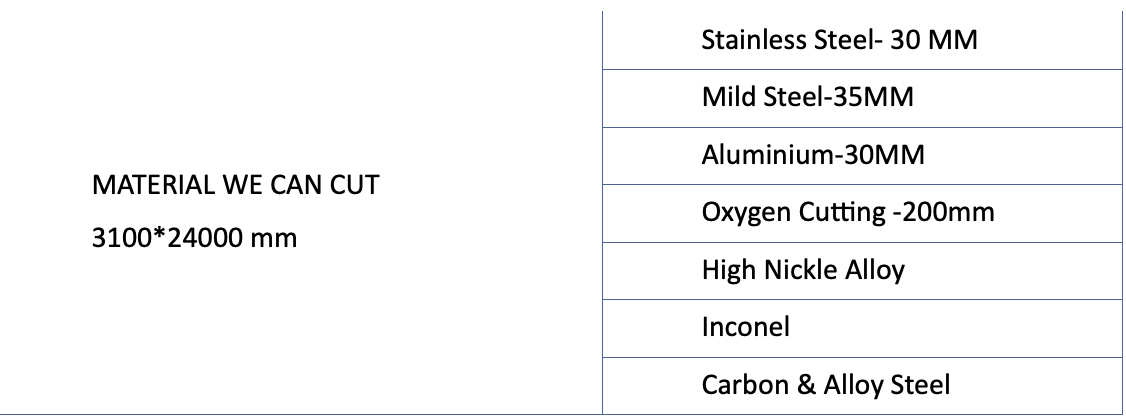

CNC Plasma and Gas Cutting

MAKE : AJAN

BED SIZE : 3100*24000 mm

CUTTING CAPACITY : 3 mm to 70 mm thick.

Utilising very modern and powerful equipment, Simmed has the capability to virtually print to order intricate parts, pieces and sections for use in multi-form fabrications as well as bespoke individual pieces. CNC powered plasma cutters backed by industry recognised CAD tools controlled by talented design staff work together to enable high class efficiency and precision accuracy with the added bonus of reduced production times. In many instances the chief engineer is able to commission a task from a design workstation (PC) as simply as printing a document to a regular printer, only in these cases the media (steel not paper) is a little more expensive.

With the Plasma Cutting machine; Plasma cutting of various materials made of materials such as sheet metal, stainless steel, brass, chrome and aluminum is performed.

As Simmed A.Ş. Sheet Metal and Steel Processing Center, we provide plasma sheet cutting service of sheet materials in desired sizes and thicknesses in line with the demands of our customers; We provide you with guaranteed services in this regard with our expert staff.

CNC plasma cutting refers to cutting various materials with plasma. Plasma is the fourth state of matter. Under normal conditions, matter exists in three states as solid, liquid and gas. However, plasma is another state of matter known to be very limited. In the plasma cutting system, the cutting process takes place by transferring the energy to a conductive material. Plasma flow typically occurs with gases such as oxygen, argon, air and nitrogen. The electric current produced by an external power source ionizes the gas stream and converts it into energy.

Compressed air is ionized with the help of a direct current power source and plasma is created. CNC plasma cutting process can be performed on conductive materials. There are some elements in the CNC plasma cutting process. The said elements are; suitable type aretorch, power supply and continuous constant compressed air. The biggest advantage of plasma cutting processes is that it is a cutting method that can be applied from conductive metals. Not only the purpose of cutting, but also the technology of plasma cutting stands out and draws attention. The plasma gas, which conducts electricity, transfers the energies to the metal in the electrical source and performs the cutting process. The devices that perform the said cutting operations are called CNC plasma cutting machines. So, which materials can the CNC plasma cutting machine cut?

What Can Be Cut With CNC Plasma Cutting?

CNC plasma cutting machines can easily cut materials with different properties. It is possible to list the materials in question as follows.

Stainless steel,

Aluminum,

Brass,

Copper,

Lama Irons produced from metals such as Silver and Titanium,

Square Irons,

Manufacturing Steel,

NPU Irons,

NPI Irons,

Transmission,

Iron Types,

Box Profiles,

Breeding Steels,

Black Sheets,

Cutting Works of Template Square Flange Press and Machine Bodies,

Angle Irons,

Galvanized Sheets,

Industrial Pipes,

TE Irons,

CNC laser cutting service is offered for different products such as Printed Door Sheets and Printed Door Sheets.

Simmed A.Ş. which provides CNC laser cutting services, carries out the cutting processes of products in 2000 x 24000 mm dimensions and thicknesses between 4 mm and 200 mm.

CNC Plasma Cutting Advantages

We can mention that there are various advantages of the CNC plasma cutting device and the cutting process in question. It is possible to list the advantages of the said cutting processes as follows.

The manufacture of all products is carried out in line with various competitions. For this reason, manufacturing companies try to produce quality products with the most affordable prices in order to gain more profit. It is possible to get the best service at the most affordable price with CNC plasma cutting services.

CNC plasma cutting prices are among the topics researched by people who want to benefit from the advantages of plasma cutting. However, it is not possible to give an exact figure regarding the prices of the said segment type. Because each company makes a pricing considering its own costs and profit rate. In this direction, we can say that Simmed A.Ş. has a special pricing.